Elastomers offer incredible sensitivity coupled with extremely long life. This results in stable set points over the life of the pressure switch as well as tight deadbands. Their biggest weakness is the increase in modulus (stiffening) that occurs at lower temperatures. This results in pressure switch set points to shift higher and deadbands to increase with decreasing temperature. They also exhibit more hysteresis than Kapton diaphragms. The Elastomer diaphragms offer excellent resistance to a wide range of chemicals and consist of outstanding environmental properties such as ozone, weather, and heat resistance.

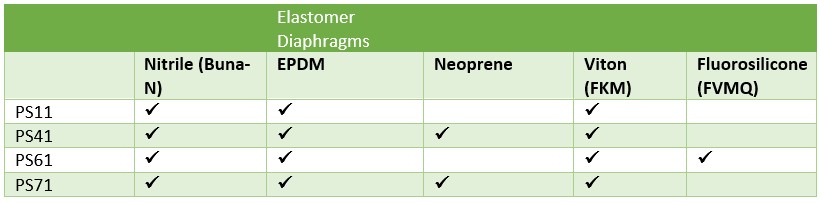

Below you will find a list of chemical compatibility with the different types of Elastomer diaphragms that we offer:

Elastomer Diaphragms

Nitrile Diaphragm (Buna-N)

- Water and petroleum-based hydraulic oils

- Mineral Oil

EPDM (Ethylene Propylene) Diaphragm

Typically used with:

- Steam, Hot Water

- Phosphate ester-based hydraulic fluids

- Ketones - Acetone

- Alcohols – Benzyl, Ethyl, Octyl

- Brake fluids

Neoprene (Chloroprene) Diaphragm

Typically used with:

- Petroleum-based mixtures – greases, oils, and solvents

- Typically specified for refrigerant systems

- Hydrocarbons

Viton (Fluoroelastomer/FKM) Diaphragm

Typically used with:

- Alcohols - Ethanol, Benzyl, Isopropyl,

- Diesters

- Solvents - Water, Acetone

- Mineral Acids - Sulfuric acid, Nitric acid,

- Synthetic oils – Hydraulic oil, transmission fluid

- Fuels – Diesel Fuel, Gasoline, Petroleum, Biodiesel

- Hydrocarbons - Hexane, Pentane, Ethane

- Also used for high vacuum service.

Fluorosilicone (FVMQ)

- Transmission fluid

- Hydraulic oil