FS (Full Scale or Full Span):

- FS defines the range of measured valves over which a sensor is intended to measure, specified by the upper and lower limits.

- For example:

- a 0 to 100 PSIG sensor’s FS is 100 PSI

- a 0 to 5 VDC sensor’s FS is 5 VDC

- a 1 to 5 VDC sensor’s FS is 4 VDC

Gauge Pressure:

- Pressure measured relative to atmospheric pressure.

- Most setpoints or measuring ranges are specified in gauge pressure because it provides an automatic method of offsetting atmospheric pressure variations caused by altitude and weather.

- Usually expressed in terms of psiG or barG.

- Blog on Gauge vs. Absolute

Sealed Gauge Pressure:

- Same as Gauge Pressure definition (above) but the electrical back end is sealed so that the device does not breathe to the atmosphere.

- Aids in keeping moisture and the environment out of the sensor.

- Typically used when the measuring pressure is 1500 psi (100 bar) so that the ignored and slight change in the atmospheric pressure does not create a significant error.

Absolute Pressure:

- Pressure measured relative to absolute zero pressure.

- Usually stated in terms of psia, torr or mm Hg.

- Blog on Gauge vs. Absolute

Compensated Temperature:

- As temperature changes, so does pressure. This is based on Boyle’s Law.

- This is defined as the temperature range that the sensor will operate within the printed specifications.

- Most Gems pressure sensors have built-in temperature monitors that sends a signal to the internal processor so that as the temperature transitions to very hot or very cold, the sensor knows this and can correct the output to be the actual pressure.

Operating Temperature:

- This is the temperature range that the pressure sensor can safely operate in and not cause any damage.

Proof Pressure:

- Proof pressure is the maximum pressure that can be applied to a pressure sensor without causing mechanical degradation (leaking) or shift in set point.

- For example, after experiencing a pressure spike above the rated proof pressure specification, a pressure sensor that used to provide an output from 1 to 5 VDC may now output 1.1 to 5.1 VDC. This is a common sign that the sensor was exposed to pressure over its proof pressure specification.

Burst Pressure:

- Burst pressure is literally the amount of pressure that will cause a pressure sensor to physically fail.

- This can lead to a leaking diaphragm or a piece of the housing becoming loose.

Long Term Drift:

- This specifies the amount of offset or drift a sensor can experience in it’s lifetime.

- Note: the specification listed in the catalog is not accumulative. It is an error that can possibly happen within one year’s time.

Span Tolerance:

- Span is defined as the algebraic difference between the limits of the sensor’s range.

- For example: a sensor with a 1 to 5 VDC output has a 4 V span.

- Span Tolerance is the small potential error over the Span range.

Pressure Port:

- The pressure port is the threaded part of the sensor that will connect the pressure sensor to the customer’s fluidic system

- The sizes and styles range from tapered styles (NPT) to straight thread styles (SAE and Metric).

- They are also available in Male and Female configurations, including a Female port compatible with Schraeder valve fittings.

Wetted Parts:

- This is the area of the sensor that gets exposed to the customer’s media or fluid.

- This can include the pressure port, the diaphragm, and the O-ring on the port.

- It is very important to ensure that you match your media/fluid with the correct wetted parts to ensure a long-lasting application.

- Standard and optional wetted parts for each individual pressure sensor series are listed on their data sheet.

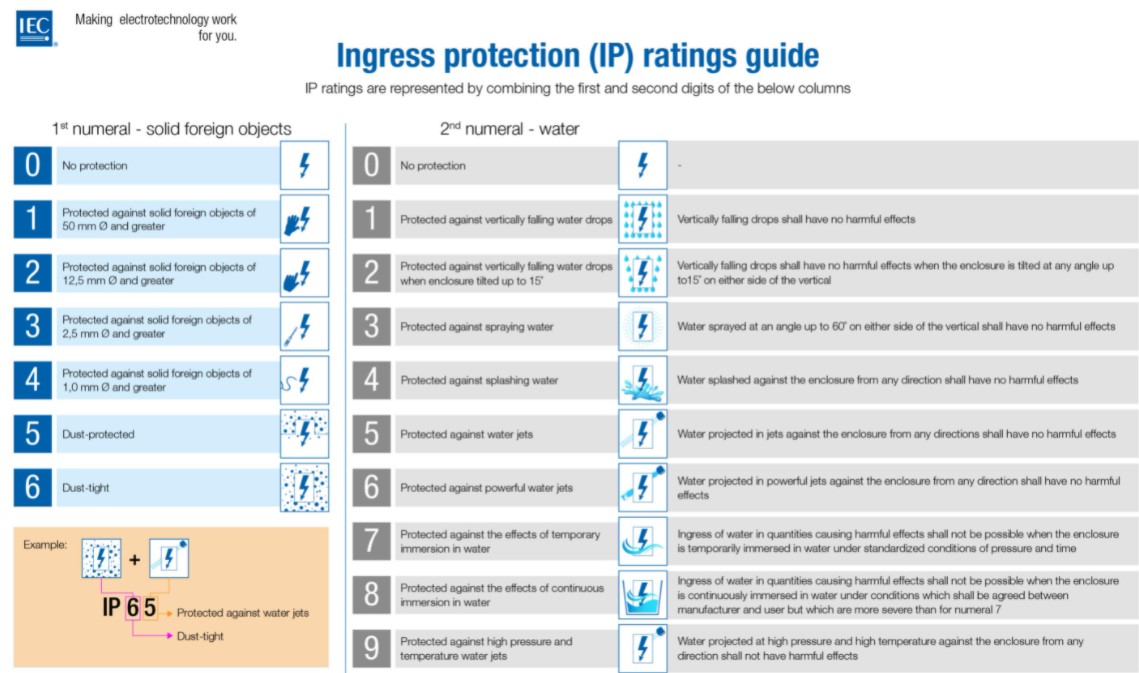

IP Ratings:

- IP stands for Ingress Protection.

- This is a rating determining how well a device is resistant to either or water or dust.

- Gems follows the IEC Standard 60529 as well as the DIN standard DIN 40050-9.

- The IEC Standard is broken down to specify the level of protection:

- First Numeral – Solid Objects Ingress

- Second Numeral – Water Ingress

Accuracy:

- Accuracy is defined as how close a measurement is to the actual, real world value.

- In the field of pressure sensors, accuracy is described as how close a sensor can produce an output in relation to the pressure that it is reading.

- There will always be a very small error in accuracy, but it is important to understand what those values are and how they can be utilized in the real world.

- Blog posting of Accuracy in the 3100 Series Pressure Sensors

Repeatability:

- The limit of deviation from the desired setpoint under a given set of environmental and operational conditions.

Learn more about our Pressure Sensor options: Here